|

The grinders Miller has the capacity to reduce various type of waste as; wood, plastic, electrical cables, paper and cardboard and other materials in particle sizes defined by interchangeable screens of various size. From the final product it will possible obtain material calibrated from 10 to 100 mm, even starting from materials of large dimensions.

|

|

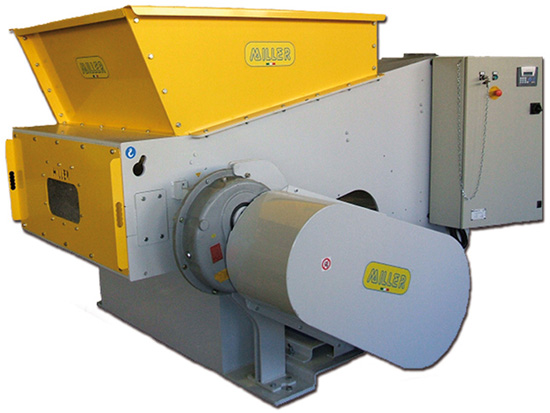

Grinder TR 800 LTA Ø 260 |

|

|

To download the forms in pdf select the language

| GRINDER TR 800 LTA 15-22 KW |

|

|

|

|

| * |

Machine body in steel Fe 510 (UNI 7746) with high thickness, welded and with guaranteed stiffness by tensioning elements |

|

|

| * |

Rotor in steel Fe 510 (UNI 7746) with high resistance with traction by commuter gearbox (with gears in oil bath) connected to the electric motor with transmission pulley / belt |

Ø |

260 |

| * |

Anti-stress device to absorbs the shocks to protect the rotor and the gearbox |

|

|

| * |

Blades in special steel reversible and easily replaceable |

N° - mm |

38 - 30X30 |

| * |

Blades supports with special rotor seats |

|

|

| * |

Counterblades in steel C45 hardened and adjustable for a better cutting accuracy |

|

|

| * |

Total installed power |

Kw |

15-22 |

| * |

Hydraulic unit to operate the hydraulic pressure that pushes horizontally the material to be treated in the rotor |

Kw |

0,55 |

| * |

Electrical panel complete with PLC and software dedicated to the control of the operating parameters; all the components are of high quality, leading brands and easily available |

|

|

| * |

Block and automatic reversal of the rotor from the PLC in case of anomalies in the control parameters |

|

|

| * |

Feeding mouth |

mm |

800X1000 |

| * |

Size of the machine |

mm |

1370X1750X1500H |

| * |

Wood/hour production with grid Ø 20 |

Kg |

350-600 |

| * |

Weight |

Kg |

1100 |

|

|

|

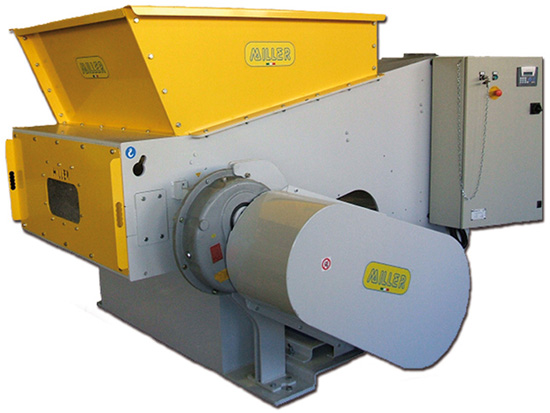

Grinder TR 800 A Ø 380 |

|

|

To download the forms in pdf select the language

CLICK HERE AND HERE TO SEE OUR TR 800 A IN OPERATION.

| GRINDER TR 800 A Ø 380 – 30-45-55 Kw |

|

|

|

|

| * |

Machine body in steel Fe 510 (UNI 7746) with high thickness, welded and with guaranteed stiffness by tensioning elements |

|

|

| * |

Rotor in steel Fe 510 (UNI 7746) with high resistance with traction by commuter gearbox (with gears in oil bath) connected to the electric motor by transmission pulley / belt |

Ø |

380 |

| * |

Anti-stress device to absorbs the shocks to protect the gearbox and the rotor |

|

|

| * |

Blades in special steel reversible and easily replaceable |

N° - mm |

42 - 38X38 |

| * |

Blades supports with special rotor seats |

|

|

| * |

Counterblades in steel C45 hardened and adjustable for a better cutting accuracy |

|

|

| * |

Total installed power |

Kw |

30-45-55 |

| * |

Hydraulic unit to operate the hydraulic pressure that pushes horizontally the material to be treated in the rotor |

Kw |

2,2 |

| * |

Electrical panel complete with PLC and software dedicated to the control of the operating parameters; all the components are of high quality, leading brands and easily available |

|

|

| * |

Block and automatic reversal of the rotor from the PLC in case of anomalies in the control parameters |

|

|

| * |

Feeding mouth |

mm |

800X1000 |

| * |

Size of the machine |

mm |

2150x1370x1870h |

| * |

Wood/hour production with grid Ø 20 |

Kg |

450-800 |

| * |

Weight |

Kg |

3000 |

|

|

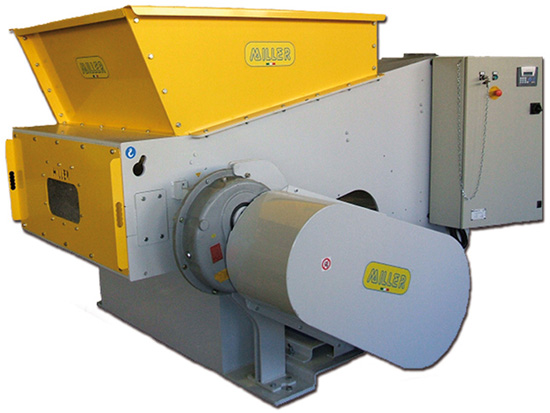

Grinder TR 1300 LTA Ø 260 |

|

|

To download the forms in pdf select the language

CLICK HERE TO SEE OUR TR 1300-LTA IN OPERATION.

| GRINDER TR 1300 LTA 30 KW |

|

|

|

|

| * |

Machine body in Fe 510 (UNI 7746) with high thickness, welded and with guaranteed stiffness by tensioning elements |

|

|

| * |

Rotor in Fe 510 (UNI 7746) with high resistance with traction by commuter gearbox (with gears in oil bath) connected to the electric motor with transmission pulley / belt |

Ø |

260 |

| * |

Anti-stress device to absorb the shocks to protect the gearbox and the rotor |

|

|

| * |

Blades in special steel reversible and easily replaceable |

N° - mm |

31 – 30x30 |

| * |

Blades supports with special rotor seats |

|

|

| * |

Counter blades in steel C45 hardened and adjustable for a better cutting accuracy |

|

|

| * |

Total installed power |

Kw |

30 |

| * |

Hydraulic unit to operate the hydraulic pressure that pusher horizontally the material to be treated in the rotor |

Kw |

2,2 |

| * |

Electrical panel complete with PLC and software dedicated to the control of the operating parameters; components are of high quality, leading brands and easily available |

|

|

| * |

Block and automatic reversal of the rotor from the PLC in case of anomalies in the control parameters |

|

|

| * |

Feeding mouth |

mm |

1500 x 1248 x 600

|

| * |

Size of the machine |

mm |

2870 x 1820 x 1520h

|

| * |

Weight |

Kg |

2300

|

|

|

|

Grinder TR 1300 A Ø 380 |

|

|

|

To download the forms in pdf select the language

| GRINDER TR 1300 A 30-45-55 KW |

|

|

|

|

| * |

Machine body in Fe 510 (UNI 7746) with high thickness, welded and with guaranteed stiffness by tensioning elements. |

|

|

| * |

Rotor in steel Fe 510 (UNI 7746) with high resistance with traction by commuter gearbox (with gears in oil bath) connected to the electric motor with transmission pulley / belt |

Ø |

380 |

| * |

Anti-stress device to absorb the shocks to protect the gearbox and the rotor |

|

|

| * |

Baldes in special steel reversible and easily replaceable |

N° - mm |

72 – 38x38 |

| * |

Blades supports with special rotor seats |

|

|

| * |

Counter blades in steel C45 hardened and adjustable for a better cutting accuracy |

|

|

| * |

Total installed power |

Kw |

30-45-55 |

| * |

Hydraulic unit to operate the hydraulic pressure that pushes horizontally the material to be treated in the rotor |

Kw |

2,2 - 4 |

| * |

Electrical panel complete with PLC and software dedicated to the control of the operating parameters; all the components are of high wuality, leading brands and easily available |

|

|

| * |

Block and automatic reversal of the rotor from the PLC in case od anomalies in the control parameters |

|

|

| * |

Feeding mouth |

mm |

1300 x 1300 |

| * |

Size of the machine |

mm |

3000X1950X1870 H |

| * |

Wood/hour production with grid Ø 20 |

Kg |

1000 – 2300 |

| * |

Weight |

Kg |

3200 - 4500 |

|

|

Grinder TR 1800 A Ø 380 |

|

|

To download the forms in pdf select the language

| GRINDER TR 1800 A 75-90-132 KW |

|

|

|

|

| * |

Machine body in Fe 510 (UNI 7746) with high thickness, welded and with guaranteed stiffness by tensioning elements. |

|

|

| * |

Rotor in Fe 510 (UNI 7746) with high resistance with traction by commuter gearbox (wth gears in oilm bath) connected to the electric motor with transmission pulley / belt |

Ø |

380 |

| * |

Anti-stress device to absorb the shocks to protect the gearbox and the rotor |

|

|

| * |

Blades in special steel reversible and easily replaceable |

N° - mm |

111 – 38x38 |

| * |

Blades supports with special rotor seats |

|

|

| * |

Counter blades in steel C45 hardened and adjustable for a better cutting accuracy |

|

|

| * |

Total installed power |

Kw |

75-90-132 |

| * |

Hydraulic unit to operate the hydraulic pressure that pushes horizontally the material to be treated in the rotor |

Kw |

2,2 |

| * |

Electrical panel complete with PLC and software dedicated to the control of the operating parameters; all the components are of high quality, leading brands and easily available |

|

|

| * |

Block and automatic reversal of the rotor from the PLC in case of anomalies in the control parameters |

|

|

| * |

Feeding mouth |

mm |

1900x1450 |

| * |

Size of the machine |

mm |

3006x2945x1990h |

| * |

Wood/hour production with grid Ø 20

|

Kg |

1800-3000 |

| * |

Weight |

Kg |

5000 |

|

|

|

|

|

|

|

Page 2 of 3 |